Article originally published as “When to shake almonds?” Revised in June 2024

Clarissa Reyes, UCCE North Sacramento Valley Orchard Systems Staff Research Associate,

Luke Milliron, UCCE Farm Advisor, Butte, Glenn, and Tehama Counties,

Franz Niederholzer, UCCE Farm Advisor, Colusa and Sutter/Yuba Counties

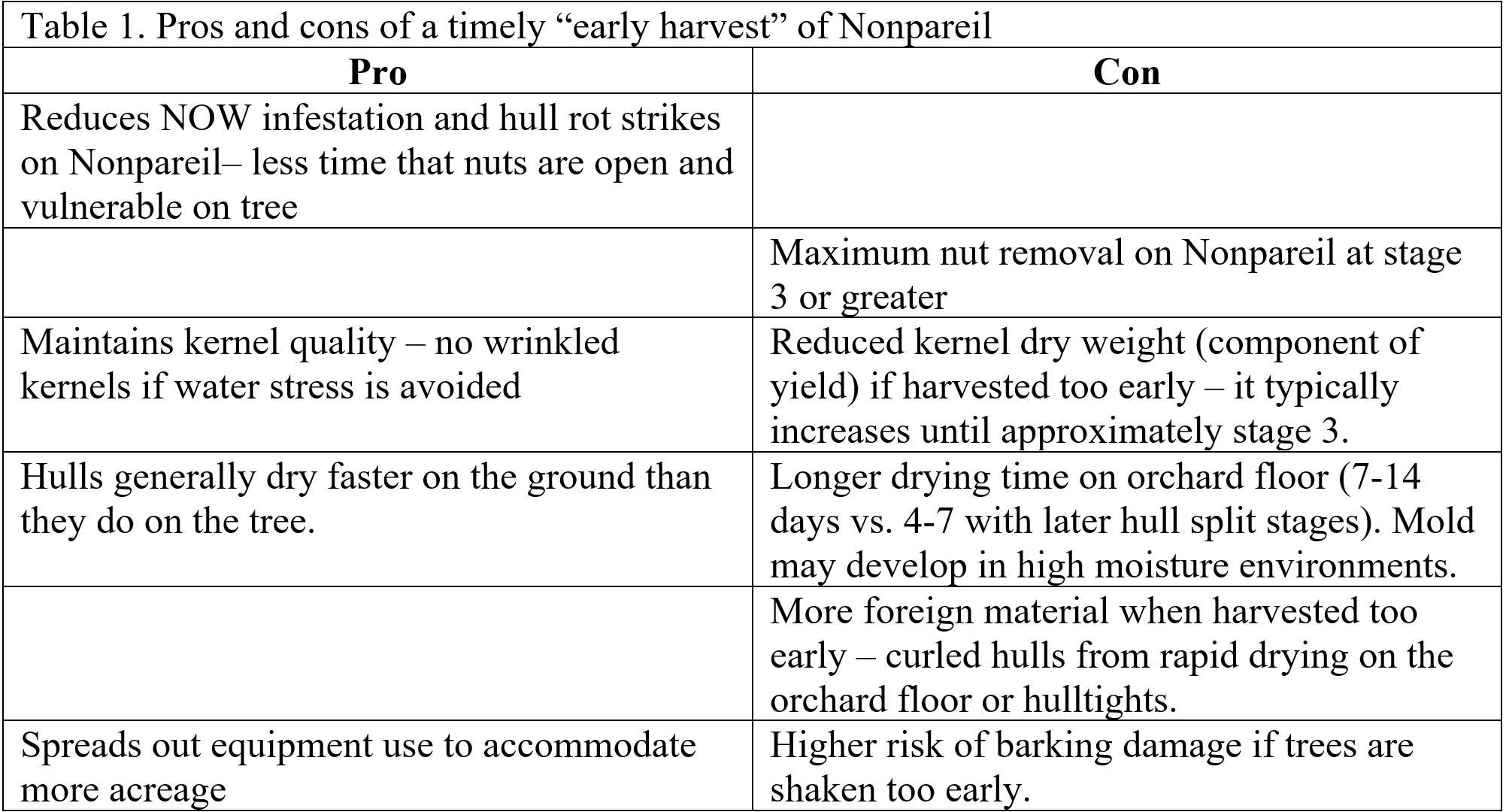

Almonds can be harvested as early as when 100% of the nuts on the tree reach hull split. 100% hull split occurs when the lowest nuts in the lower interior canopy reach stage 2C (Figure 1): there is a deep V at the suture and the nut splits open when hand pressure is applied to opposite ends of the hull. Historically, the recommendation from UC almond experts for the ideal time to shake was as soon as 100% hull split occurred, keeping in mind pest and disease management, nut removal/drying time, and nut quality. However, these considerations vary widely among varieties and locations, so we’d like to address potential challenges that growers should consider when timing harvest, with additional notes on this year’s specific challenges.

Figure 1. Almond hull split stages (photographs by C. Reyes and L. Milliron)

1. No separation of suture.

2A. Less than 50% of suture line separated

2B. Deep V over 50% of suture line separated, the hull cannot be squeezed open.

2C. Deep V over the entire suture line can be squeezed open by pressing opposite ends of the hull.

3. Suture opening less than 1 cm (1/2”) in width, exposed shell; visible brown edge along the split edge of the hull when observed from beneath the canopy.

4. Suture opening more than 1 cm (1/2”) in width, fully exposed shell.

5. Hull edges begin to dry, shell changes from white to brown.

6. Completely dry hull, brown shell.

Pest and disease management:

Timely harvest with rapid removal of dried nuts from the orchard floor is an effective way to manage navel orangeworm (NOW) by reducing the amount of time a nut is vulnerable to infestation. NOW pressure is high this year due to increased overwintering populations, so a timely harvest may be especially valuable in reducing NOW infestation risk this year. In general, further NOW infestation is much lower once nuts are shaken to the orchard floor.

Timely harvest can also reduce the incidence of hull rot in trees by reducing the amount of time a nut is open and vulnerable to infestation by fungi, and by reducing the amount of time an infected hull may transfer the toxin through the shoot.

Rapid removal of nuts from the ground can minimize ant infestation, and a new invasive beetle Carpophilus truncatus (CT) where present. However, shaking at an earlier hull split stage (greener hulls) can mean longer drying times on the orchard floor and greater susceptibility to ant and CT damage. (Note: at the time of this writing, in June 2024, CT has not been detected in the Sacramento Valley)

Nut removal/drying time:

If shaken when hulls are still very green (stage 3 or earlier), nuts will require longer periods of drying time on the orchard floor. Conditioning windrows may accelerate drying on the ground, and potentially provide benefits of getting cleaner product from the field, speeding up the actual “pick-up” process, and reducing hulling/shelling costs (since hullers charge on incoming weight). It is necessary for nuts and hulls to be dry when delivered to the huller because stockpiling nuts with high moisture content is detrimental to nut quality.

For Nonpareil at stages 4-5, the abscission zone (the separation zone between the fruit and the peduncle) has formed, nuts are only attached to the tree by a few fibers, and removal is normally excellent. Nonpareil normally shakes very well with an early harvest timing of 100% hull split. Unfortunately, we don’t know the ideal shake timing for each variety. The industry is still learning when to shake ‘Independence’ for maximum nut removal, with some growers swearing by an earlier shake, and others by a later shake.

A timely early harvest of Nonpareil typically requires an earlier water cutoff. Hulls dry more quickly on the ground than when nuts are attached to the tree, thus advancing harvest. However, a longer drying time on orchard floor, 7-14 days with early harvest vs. 4-7 days with later hull split stages, can prolong the time between irrigation and harvest for later-maturing varieties. To avoid water stress on later-maturing varieties, irrigation with drip or micro sprinklers can be applied between variety harvests. If this is not possible, severe water stress may result in sticktights (nuts stuck in the tree) and/or hulltights (green hulls shriveling and drying tight around the nut). ‘Winters’, ‘Padre’ and other mid- to late-harvesting varieties can be posterchildren for sticktights when water stress and a late shake combine. An excessively late harvest can also result in mite infestation, and defoliation on later-maturing varieties. Extreme defoliation robs the tree of carbohydrates and can reduce bloom the following spring.

In some areas of California, smoke from nearby wildfire events traps moisture in the air, extending overall drying time. This impacts hull moisture, harvest readiness, and drying time on the orchard floor. If smoke causes delayed drying and increased drought stress on trees, sticktights and/or hulltights can occur. If so, this may reduce nut removal and/or require shelling at the huller to remove the hulls, which can cause the grower to miss out on inshell premiums on a portion of the delivery.

Almond bark “tightens” and is less vulnerable to shaker damage as the harvest season progresses. Limiting trunk damage (“barking”) risk at early harvest of Nonpareil requires attention to hull split status throughout the orchard. Localized areas of delayed hull split relative to the rest of the orchard may exist due to higher soil moisture (heavy clay streak, uneven irrigation distribution uniformity (DU), low spots in the orchard, etc.). These trees may not shake “clean” at the same time as the rest of the orchard. Trees with delayed nut maturity may be shaken harder by a less experienced, poorly trained operator trying to “get all the nuts off”, resulting in trunk damage that limits the tree life and orchard productivity if enough trees are damaged.

Nut quality:

Stage 5 and 6 nuts have the highest chance of being cleanly hulled and receiving an inshell price premium. Harvesting too early can prevent color from developing on the pellicle (kernel skin), which reduces nut quality. Shaking early can also result in nuts that form curled hulls from rapid drying on the orchard floor. These curled hulls are similarly sized to kernels, difficult to separate, and may contribute to increased foreign material.

There are many factors that influence almond harvest time, including equipment scheduling, weather, irrigation timing, NOW pressure, and the potential of an inshell premium with shaking at a later hull split stage. With all these things in consideration, it is important for growers to prioritize their goals for the crop. Growers must account for site-specific challenges whereby subtle changes in the date of shaking help to mitigate costly problems with pests and diseases, nut removal, and nut quality.

Leave a Reply