Franz Niederholzer, UCCE Farm Advisor, Colusa and Sutter/Yuba Counties

Domena A. Agyeman, UCCE Ag and Natural Resources Economic Advisor; Butte, Glenn, and Tehama Counties

Almond growers are in a long tunnel of low prices and high costs. With volatile nut prices largely out of grower control, cost management and cost-effective yield improvements offer the best hope of maintaining headway and reaching the light. This article focuses on small changes in proven practices with the potential for generating positive returns for growers. The 5% rule, introduced by Danny Klinefelter, is a simple farm improvement framework that focuses on making incremental 5% improvements in cost, yield, and price, ultimately driving larger overall profitability.

Cost savings…

- Gear up, throttle down spraying. Increasing PTO sprayer speed while reducing power (higher tractor gear + lower RPMs) saves time and diesel without impacting pest management in the winter and spring. For example, if a sprayer delivers good summer pest control at 2 MPH, it should do a good job at 3 MPH (in that same orchard) from dormant through petal fall timing.

- Evaluate potassium (K) fertility programs. Is the entire K budget applied in the fall, before the crop is set? The nuts are the largest user of K in an almond tree (95 lbs K2O/1000 lbs of kernel crop. Variable bloom weather means orchard K needs may vary from year to year. Consider switching from all dormant K application to all in-season or 50% dormant and 50% in-season. In my experience, dry field-grade K fertilizer banded in the orchard in early spring where irrigation water reaches the fertilizer is an effective K source for that crop. Why bet the pot before the cards are dealt?

- Improve nitrogen (N) fertilizer efficiency. Spoon-feed N fertilizer = better results per lb N fertilizer. More and more I’m hearing of growers applying some N every week or every other week from March through May. Check leaf N levels in May and/or June to ensure enough N is getting into the trees.

- Cover crops help increase rainwater infiltration and so improve salt leaching compared to bare ground. In addition, flowers from certain cover crop species are pollen sources (food) for bees and may help lower beekeepers’ costs and perhaps a grower’s bee bill.

- Mulching with compost or other organic matter (almond shells, etc.) can improve rainwater infiltration and provide nutrients to the soil (especially K). Potassium added to the soil increases with original K concentration of the mulch material and rate of water passing through the mulch (rainwater and/or irrigation).

- Eliminate fertilizer inputs (other than N, K, B, and Zn) not improving yield.

Yield improvements…

- Check orchard boron, add when needed. If orchard B levels are low to adequate (<120 ppm B in harvest hull samples), just 0.4 lbs B/acre in a fall spray can increase yield significantly (100-200+ kernel lbs/acre in UC trials). Talk with your CCA about a boron plan. Fall and pink bud timings are key to improving yield with boron foliar fertilization if hull analysis shows a need.

- Rent bees for self-fertile varieties. In a recent study in California, the number of bee visits to flowers in a solid Independence variety orchard with no rented bees was half the number of bee visits when one hive/acre was stocked IN the orchard. This was not an isolated location but surrounded by almond orchards and rented bee hives. This difference in bee visits/flower resulted in a 45% reduction in yield where no hives were stocked in the study orchard. Using more than one hive per acre did not improve yield. The study authors recommend 0.5 – 1 hive/acre stocking rate in Independence blocks.

- Irrigation: Match water use to orchard need as measured by soil moisture or plant water status (pressure chamber, FloraPulse, etc.). Extended water stress, especially between 90% hull split and harvest, can reduce yield 5-10% by reducing kernel size.

- Evaluate orchard sanitation (mummy removal/destruction) and spraying practices to ensure the best possible navel orangeworm (NOW) and Carpophilus truncatus (CT) beetle management and maximize nut quality and yield.

These are a few ideas for research-based cost trimming or yield improvement. Growers and advisors (CCA, PCAs, processor representatives, etc.) will have additional ideas. Even a small amount of saving or income increase can make a big difference compared to not making those steps.

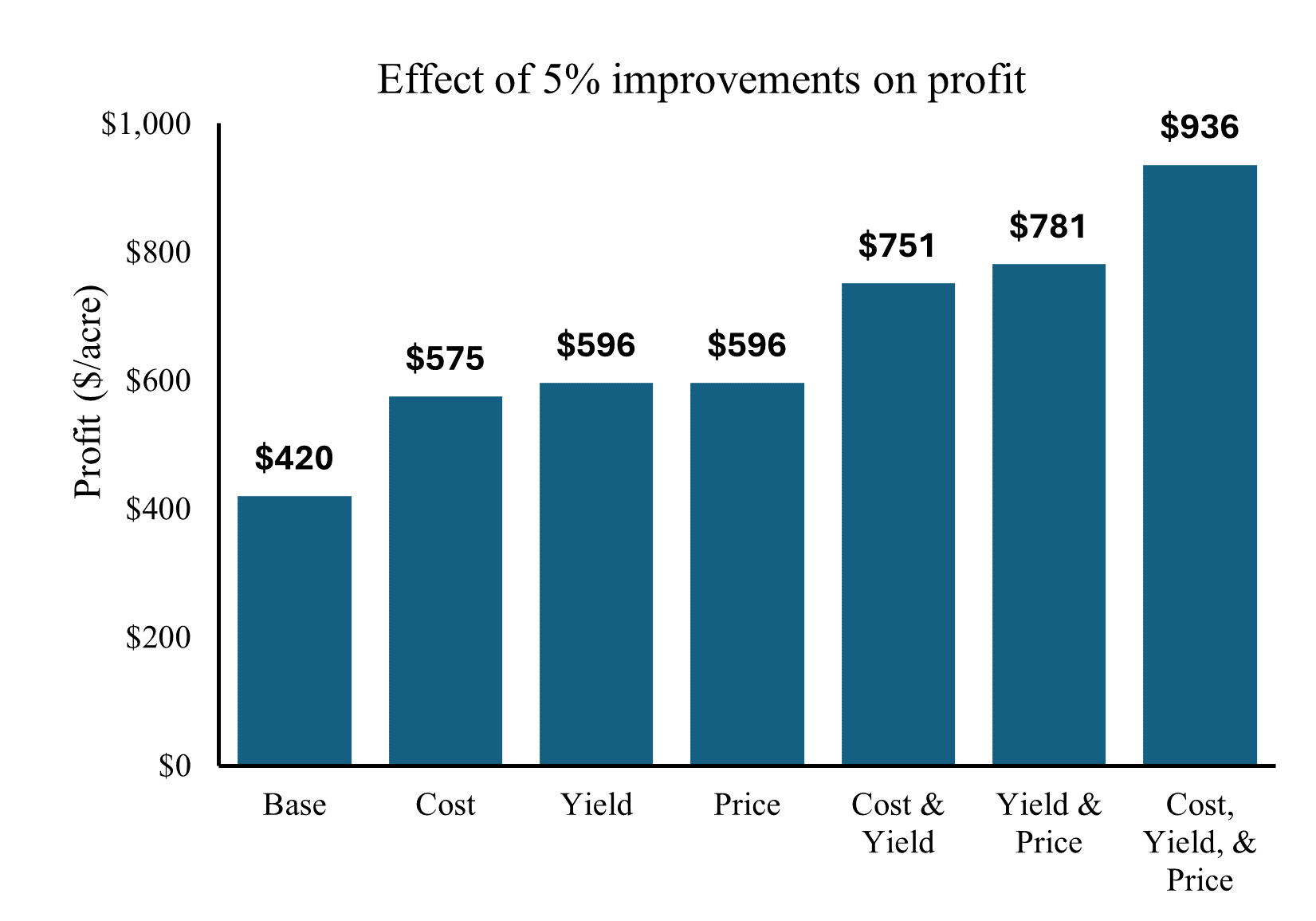

Adopting these proven cost saving and yield improvement practices for small changes can lead to significant gains. The 5% rule is a simple concept where growers should aspire to increase yield and price received by 5% and decrease cost by 5%. Figure 1 shows how 5% improvements in cost, yield, price, and their combinations affect profits. The example is based on an initial profit of $420/acre, which is determined by subtracting the base cost of $3,100/acre from the revenue, which is the product of the base yield (2,200 lb/acre) and price ($1.6/lb). A 5% decrease in cost results in a 37% profit increase, while a 5% improvement in yield or price leads to a 42% profit increase. If the price remains unchanged, but costs are reduced by 5% and yield increases by 5%, profit grows from $420/acre to $751/acre, representing a 79% increase. A combined 5% improvement in cost, yield, and price results in a 123% increase in profit.

Figure 1. Effect of 5% improvements in cost, yield, price, and their combinations on profits.

The combined effect of these 5% improvements is greater than a simple sum of 5% + 5% + 5% (for a 15% increase) because the relationship between production, marketing, and cost is multiplicative. As a result, multiple consecutive years of 5% improvements will also produce more than a 15% increase in profit, compounding over time to generate significantly larger gains. The big picture of this concept is to target small improvements in multiple areas of your operation. Adoption of this rule is characteristic of the top 20% farm businesses and a key factor in the success of great farm businesses. For example, the top 20% of corn growers in 2021 had higher yields, received higher prices, and had lower costs.

The concept is straightforward, but achieving 5% changes is not necessarily easy. However, it offers strong motivation for continuous improvement without requiring major management changes that could risk affecting yield or quality, while still boosting grower income.

Leave a Reply